a淀粉的性能特点 THE PERFORMANCE CHARACTERISTICS OF A-STARCH INCLUDE

能够提高型砂的热湿拉强度增加型砂韧性和铸件模型表面光洁度、型砂表面的a淀粉受热 燃烧后产生空隙,可以缓冲硅砂受热膨胀。从而大大提高型砂的抗夹砂能力。

The addition of a-starch to foundry sand can enhance its thermal-wet tensile strength, increase sand toughness,and improve the surface finish of casting molds.When heated, the a-starch on the sand surface combusts and forms voids,which can buffer the expansion of silica sand.This significantly enhances the sand's anti-sand-sticking ability.

● 能够降低型砂与模样之间的磨擦阻力,提高型砂的起模性,减少由于起模不良而出现的 型废率有效的减少了铸件出现的缺陷问题。

The addition of a-starch to foundry sand can reduce friction between the sand and the pattern,enhancing sand mold release and reducing the rate of sand waste due to poor release.This effectively minimizes defects in castings.

先进的加工工艺(晶体膨胀热熔)

● 如果湿砂型在合型以前放置一段时间,型砂表面失水而致表面强度下降和容易磨损,

浇注金属液时易被冲蚀。放置时间较长或者天气较干燥时,问题更为严重。型砂中加入龙祥 a淀粉可以提高型砂的抗风干能力,减少铸件冲砂缺陷。

If green sand molds are left standing before closing the mold,the surface of the sand may

lose moisture,resulting in reduced surface strength and increased wear.During metal pouring, hese weakened areas are prone to erosion.This issue is more severe with longer standing times or in dry conditions.Adding Longxiang a-starch to the foundry sand can enhance its resistance to drying and reduce the occurrence of sand-washing defects in castings.

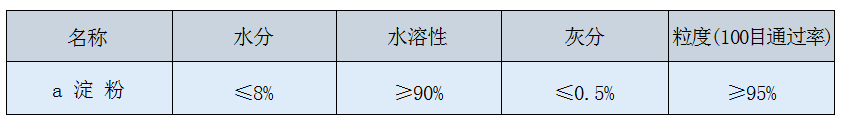

●a 淀粉的物理指标 The physical properties of A-starch are as follows 水分小于8%,水溶性大于90%,灰份小于0.5%,粒度(100目通过率)大于95%

执行技术标准 Technical standards compliance.

| 上一条:Efficient 煤粉 | 下一条:会员证书 |

坐机:0537-4591448

坐机:0537-4591448 地址:中国 山东 济宁 曲阜市 石门山镇衡庙工业园

地址:中国 山东 济宁 曲阜市 石门山镇衡庙工业园